About

The PhotoReAct project, coordinated by dr. Timothy (Tim) Noël of the University of Amsterdam (UvA), has been awarded a European grant of €3.99 million to undertake research with the aim to overcome the current limitations towards the applicability and scalability of photochemical transformations. The PhotoReAct Innovative Training Network establishes a training network with 10 beneficiaries from academia and 4 beneficiaries from industry to tackle the challenges associated with photocatalysis in a coherent and comprehensive fashion.

Introduction, objectives and overview of the research programme

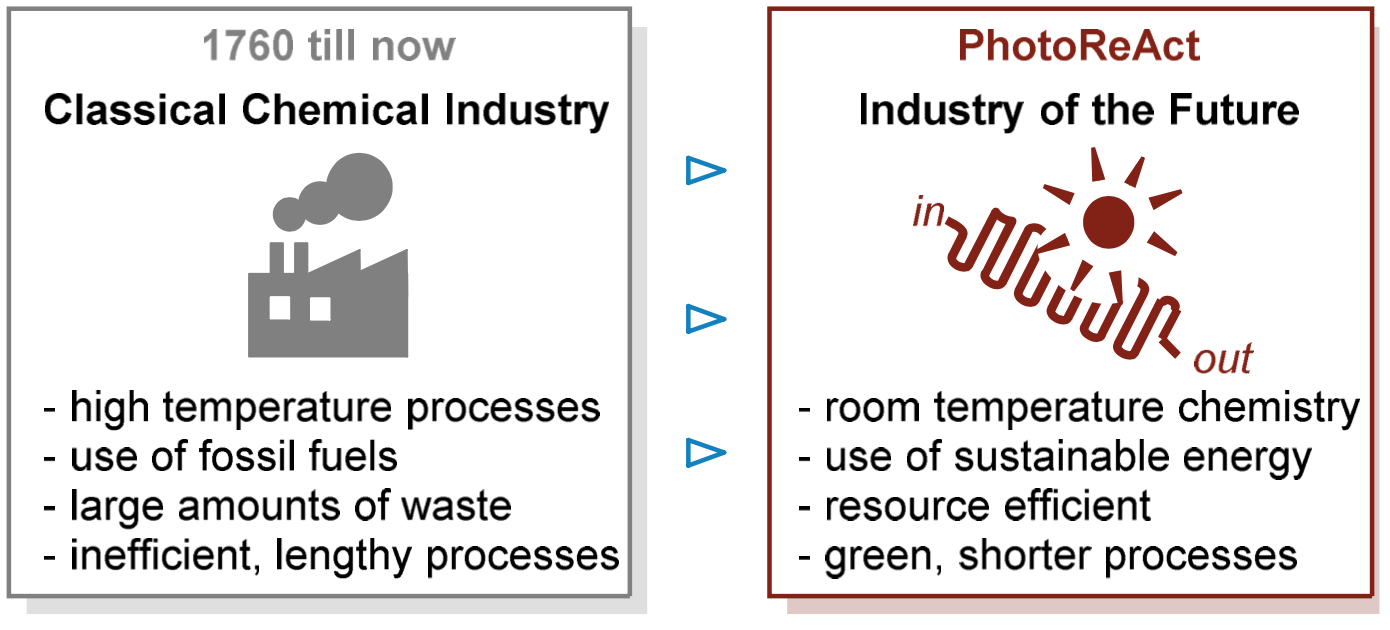

The chemicals industry uses more than 20% of all resources to generate energy and end-user products. Consequently, it can be held responsible for >20% of the global CO2 output. The Chemistry 4.0 & Industry 4.0 initiatives are devoted to improving energy- efficiency of the chemicals industry through the use of disruptive technologies and process intensification. It is the vision of PhotoReAct that the use of alternative energy sources in the chemicals industry is key to not only reducing its fossil fuel consumption, but also reducing its overall energy consumption while increasing the efficiency and selectivity of key chemical transformations. It is our aim to achieve this vision by using light energy as a reactant to produce fine chemicals, pharmaceuticals, agrochemicals and other specialty chemicals. This will lead to a European chemicals industry that is more energy efficient, and less dependent on fossil fuels while also gaining capability to deliver cutting-edge technological solutions. Indeed, in the near future, we will witness a massive energy transition from fossil fuels to sustainable energy sources, with a focus in particular on solar and wind energy. Given its carbon footprint and the existential threat of climate change, it is evident that that the chemicals industry must implement solutions to reduce its CO2 emissions (Figure 1). The sun is the most sustainable light source available; therefore, the direct use of sunlight for photochemistry is extremely appealing.

Figure 1. PhotoReAct’s foreseen energy transition in the chemical industry

Figure 1. PhotoReAct’s foreseen energy transition in the chemical industry

In the last decade, a myriad of novel visible-light mediated photocatalytic transformations have been developed that are of interest to the pharmaceutical, agrochemical, fine chemical and materials science sectors. These reactions are ideal for solar applications since they use photocatalysts capable of being photoexcited by visible light. Since often no other reagents are needed to initiate the reaction, photochemistry can be regarded as an efficient and green activation mode of organic molecules, which avoids additional reagent waste and simplifies product purification.

However, despite the apparent advantages, implementation of photons in organic synthetic methodologies and in the industrial production of fine chemicals remains challenging. This is due to a number of chemistry and technical reasons, such as inefficient photocatalysts, no general activation mode of molecules, complex reactor setup, and Beer-Lambert light attenuation effect resulting in limited scalability. Moreover, a dearth of educational tools keeps the field from moving forward, where we note there is a lack of skilled teachers, adequate courses and structured training modules. Through intense cross-disciplinary, intersectoral and international collaborations, the PhotoReAct European Training Network will tackle the technical and educational challenges associated with the implementation of photocatalysis in the chemicals industry by establishing a research and training community devoted to educating the next generation of ESRs. The training of these 15 ESRs will lead to an identification of the current knowledge gaps and how to address these. We will disseminate the potential of photocatalysis and transfer the developed technologies into commercial applications via our industry participants (both technology suppliers and end-users). After the conclusion of PhotoReAct, the obtained results and expertise will be made widely available such that other research organizations and industry can benefit.

PhotoReAct will make important contributions to the applicability and scalability of photocatalytic processes through the design of novel photocatalysts, new photocatalytic methodologies, cutting-edge technological solutions to enable automation and scalability and immediate industrial implementation.

PhotoReAct unites the efforts of an interdisciplinary and dynamic network of leading European academic groups and industry partners. The network addresses systematically the aforementioned challenges by training, mentoring and educating 15 highly skilled ESRs and by delivering innovation potential for SMEs and established industry partners. It is our ambition to pursue the following topics: (i) Development of new generations of highly effective photocatalysts that can be prepared on large scale, are cheap and based on sustainable materials (WP 2; ESR 1-5). (ii) New synthetic methods that can be used to synthesize life-saving drugs efficiently (WP 3; ESR 6-10). (iii) Advanced technological solutions to facilitate photocatalysis (WP 4; ESR 11-13). (iv) Immediate industrial implementation (WP 5; ESR 14-15). The ESRs will receive a comprehensive interdisciplinary training program through local measures and network-wide activities on topics that include: synthetic organic chemistry, photocatalyst design, homogeneous photocatalysis, and process and reaction engineering. Each ESR will carry out three secondments: (1) intra-network with their secondary supervisor; (2) international academic with world-leading groups linked to photocatalysis and photophysics; (3) with an industry partner to provide real-world experience. These secondments ensure a diverse and holistic training experience and a strong link with industry where the ESR can develop vital application expertise. A number of measures, including the establishment of Erasmus+ partnerships, and the recognition of training elements towards long term joint PhD programs ensure that PhotoReAct leads to long-lasting collaborations among the different partners.

Through strong industry-academia partnerships, PhotoReAct facilitates the uptake of scientific results of photochemical

applications. More specifically, PhotoReAct addresses the following targets:

• Scientific target: Results obtained in PhotoReAct will be published in leading scientific journals (4 papers/ESR), made available through open access and with supporting data also made freely available, subject to IPR considerations (vide infra). Upon conclusion of the program, all results will be summarized in a textbook.

• Training target: PhotoReAct will train 15 ESRs in multidisciplinary scientific and soft skills and will enable training collaboration between network partners.

• Industry involvement target: PhotoReAct will support the industry beneficiaries to report at least one successful product or process before the end of the project.

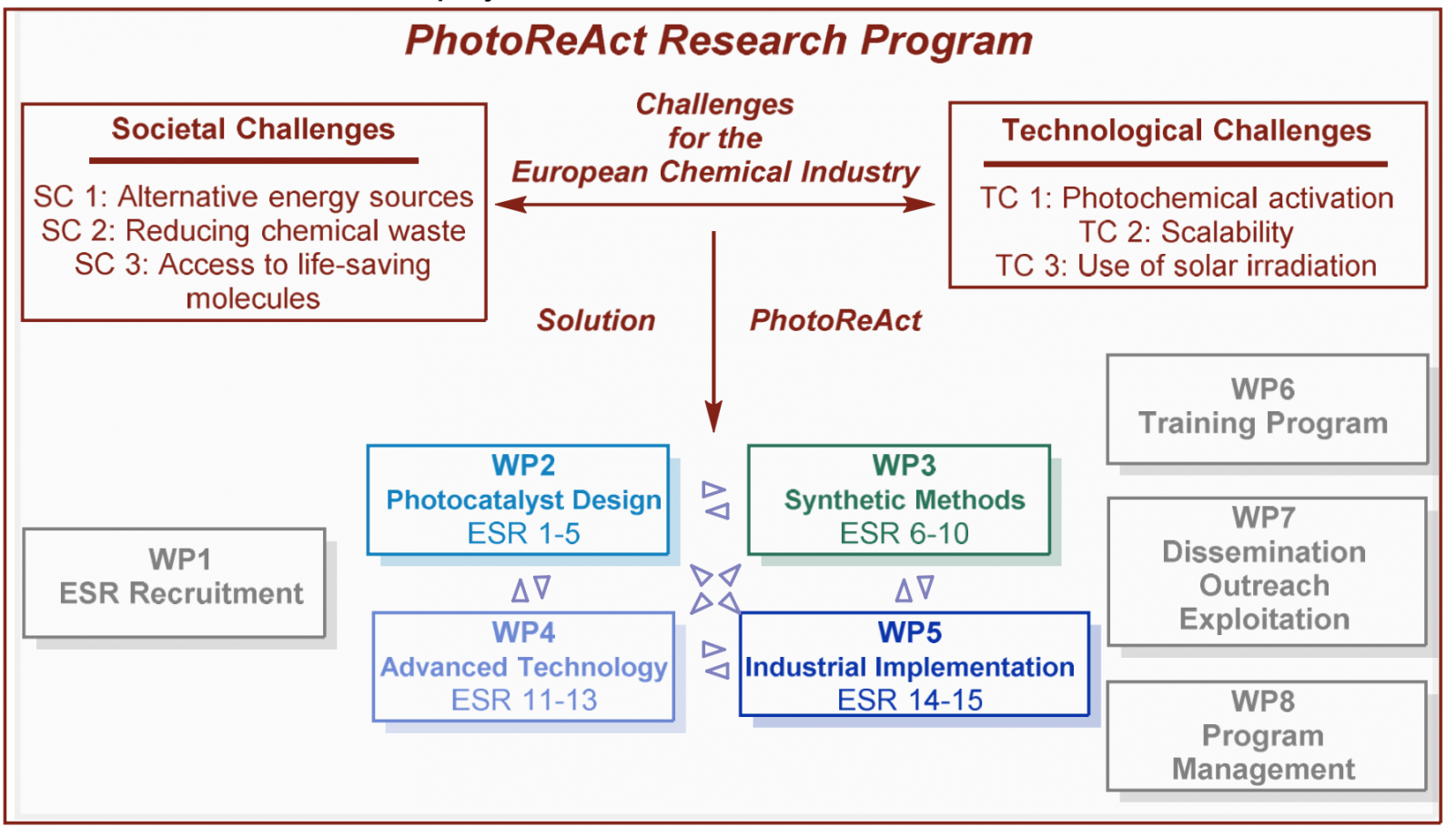

Figure 2 provides a global overview of the different societal and technological challenges and the resulting different research lines and scientific objectives of the PhotoReAct program. Through intense and sustained collaboration, our network aims to achieve substantial breakthroughs in the field of photocatalysis covering the following different societal and technological challenges relevant to the European Union and Market.

Figure 2. Overall challenges and Work Package overview of the PhotoReAct program.

Figure 2. Overall challenges and Work Package overview of the PhotoReAct program.

SC1: Alternative energy sources for chemical processes in industry. The chemicals industry is still reliant on the use of thermochemical activation pathways, which requires the use of fossil fuels to generate the required energy. Despite access to an essentially infinite amount of solar energy, this energy source has seen only limited use in the chemicals industry. The PhotoReAct program aims to overcome the chemical and technological barriers, which prevents the market penetration of photocatalysis.

SC2: Reduction of chemical waste. The use of toxic solvents, stoichiometric amounts of reagents, including toxic radical initiating reagents, the often-limited selectivity, as well as the inefficiency of chemical processes on an industrial scale lead to the production of significant amounts of waste. Development of new and improved photocatalytic transformations as delineated in this proposal will address the production of chemical waste. Moreover, the development of new photocatalysts based on sustainable materials in combination with continuous-flow reactors (e.g. micro- and milli-reactors), together with (a) optimization of the radiation and mass transport phenomena in these reactors and (b) input from mechanistic studies on photocatalytic transformations, will further improve the efficiency of the photochemical processes for industrial applications.

SC3: Fast and reliable access to life-saving molecules. In the modern fine-chemical, pharmaceutical and agrochemical industries, a fast and facile implementation of chemical processes from laboratory to industrial scale is crucial. Fast but accurate data acquisition in automated flow platforms is essential in the early development phases to facilitate this transition. The PhotoReAct network will focus on the design and implementation of such standardized models. In addition, the development of scalable photocatalyzed processes will be established allowing to bring the methodology to an industrial scale.

TC1: Suitable, visible light photo activation of organic molecules. Many molecules can only be directly activated through use of UV irradiation as they only absorb in that part of the electromagnetic spectrum. In the past decade, photocatalysis has offered the potential to use visible light as an energy source to initiate chemical transformations. New and improved photocatalytic transformations and catalysts will be developed in the PhotoReAct network. Important in the development stages will be the synthetic application (as identified by the industry partners, e.g. specific steps in the preparation of pharmaceuticals or agrochemicals) and the compatibility with the reactor design.

TC 2: Scalability of photochemistry. One of the major issues encountered in traditional photochemistry is the distribution of photons with increasing reactor dimensions. The attenuation effect of photon transport (Beer-Lambert law) prevents efficient scaling to what is required in the industry. In the PhotoReAct network, continuous-flow reactors with small characteristic dimensions will be used to ensure scalability from a laboratory scale to pilot scale and finally to small production scale.

TC 3: Use of green and sustainable solar irradiation. The use of solar energy as an infinite source of green and clean energy is essential to reduce the chemicals industry carbon footprint. Within PhotoReAct, we will actively promote alternative light sources, i.e. (i) the irradiation with energy-efficient LEDs, which are driven by sustainable electricity and (ii) the use of solar light directly via so-called LSC-based photoreactors.

Market value of photocatalysis. While visible light photocatalysis, including photoredox catalysis, is a relatively resurgent field whose renaissance dates back only 13 years or so, its implementation in industry has been slow but now is rapidly expanding as it has met with great enthusiasm. Indeed, most pharmaceutical companies have now a small team that implements photoredox catalysis into their medicinal chemistry programs where rapid and efficient transformations on complex target substrates are highly valued. The presence of large agrochemical (partner, Syngenta) and fine chemicals (beneficiary, Johnson Matthey) companies within PhotoReAct is further evidence of the desire of these industries to incorporate photochemical transformations into their program. Furthermore, in recent years, specialized equipment providers have launched dedicated products to facilitate photocatalysis and its scale up (including beneficiary Comminex and partner CreaFlow).The advantages of photocatalysis are the mild activation mode (at room temperature, use of visible light, avoidance of toxic redox reagents), synthetic strategies to build up complex molecules and the opportunity to late stage modify functionally complex compounds to the inherent chemoselectivity of these transformations. The latter generates not only attractive and shorter synthetic routes but also new Intellectual Property opportunities. Current outstanding research questions relate to rational photocatalyst design (WP 2), new synthetic strategies to build agrochemicals, fine chemicals and pharmaceuticals (WP 3), scale up (WP 4), use of solar energy (WP 4) and implementation in drug discovery programs (WP 5). All of these issues will be tackled by the ESRs within PhotoReAct and their progress will pave the way to new scientific opportunities and applications of photocatalysis.

Research methodology and approach

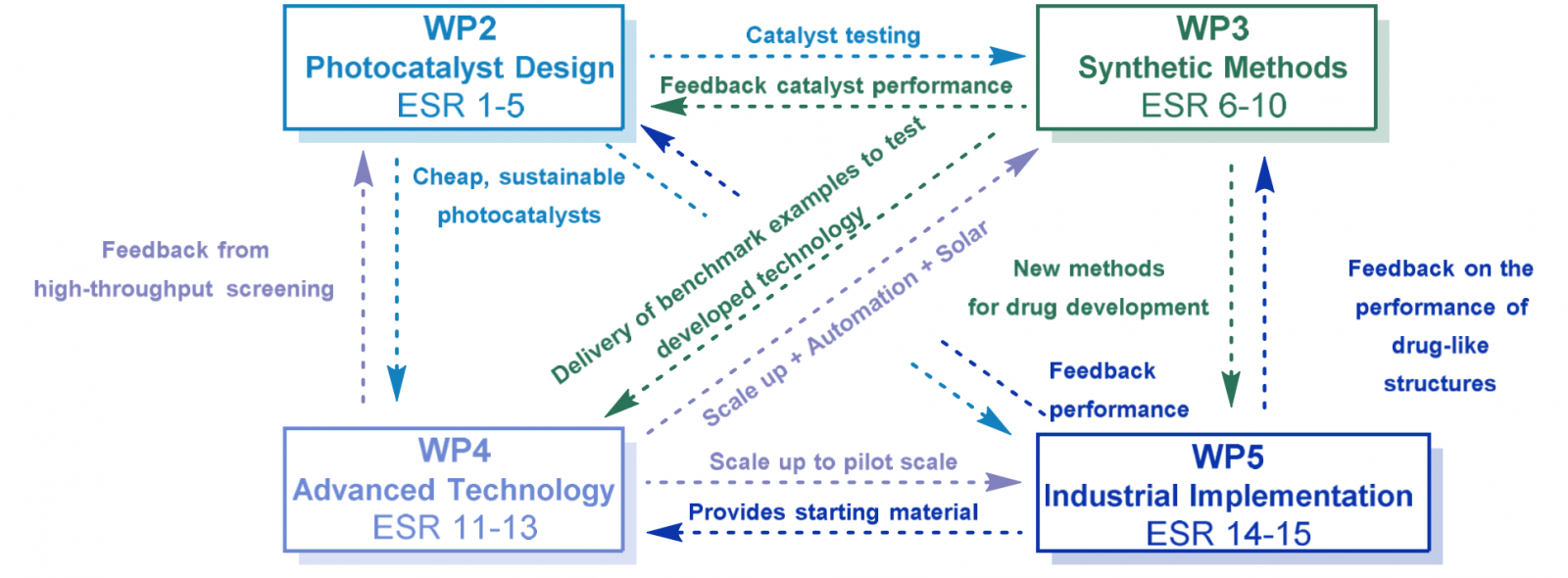

PhotoReAct is organized into 8 WPs (Table 1). After recruitment of the ESRs (WP1), the research program (WP2-5) will be initiated. These WPs

(WPs 2-5, see Fig. 3) follow the classical development cycle of any chemical transformation and technology. Continuous feedback and feed forward of the data will take place between WPs 2-5 to iteratively integrate and optimize photocatalyst design, synthetic methodology development, photocatalytic technology and industrial implementation, which will ultimately strengthen the individual WPs.

Figure 3. PhotoReAct's main collaborative research interactions

Figure 3. PhotoReAct's main collaborative research interactions

Unique within PhotoReAct is that the fundamental research on photocatalysis (WP2 & 3) and photocatalytic technology (WP4) will percolate directly into industrial applications (WP5). Details on the interaction between the individual ESRs and the partner organizations are described below. Section 1.1.3 identifies the state-of-the-art, main innovative aspects of the individual research programs and related key performance indicators. The training program of each ESR will be organized and continuously monitored (WP6). WP7 ensures proper dissemination of the research results, the transfer and exploitation of knowledge and IP and organizes the outreach activities. WP8 covers the program management activities.

Table1. WorkPackage(WP)List.